Why use a limit switch?

Safety and reliability

One of the most important reasons for using a limit switch is safety. Machines and installations can be dangerous if moving parts do not stop in time. A limit switch prevents shafts, lifts, or conveyor belts from moving beyond their end position. This protects both the machine and the user.

In addition, a limit switch ensures reliability: the switch always gives a clear signal as soon as a preset position is reached. This prevents overload or damage.

Automation and efficiency

In modern production environments, everything revolves around automation. A limit switch plays a crucial role in this.

When a machine component reaches a certain position, the limit switch switches automatically. This allows a process to start, stop, or switch to another phase without the need for manual operation. This saves time and reduces the risk of human error.

For example, a mechanical limit switch can stop a conveyor belt as soon as a product reaches the end position, or bring a lifting bridge to a safe stop.

Precision and control

For applications where accuracy is of paramount importance—such as in CNC machines or automation lines—a **limit switch** is indispensable.

Moujen limit switches are therefore widely used in the industrial world. Do you have a question about the use of a limit switch in your field of work? Feel free to contact us.

The switch ensures that machines always recognize the same reference position. This makes it possible to work with high precision and repeat processes without deviations.

A concrete example is the Moujen limit switch: it is known for its durability and accurate operation, which is why it is often used in industrial environments where reliability and precision go hand in hand.

Conclusion: a limit switch is an essential component for safety, efficiency, and accuracy in countless machines and systems.

Curious about the situations and environments in which you can use a limit switch? Read our blog: When to use a limit switch?

MEA-9122

- IP-: 65

- AC Rated: 6A 125-250V

- Actuation Sequence(s): Double Break(1) Double Make(2)

- Contact Form(s): Form Z

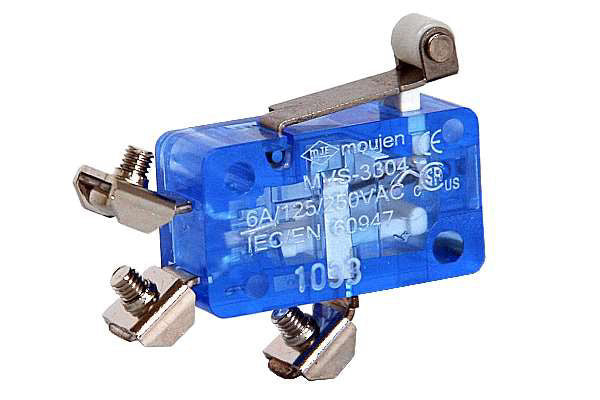

MVS-3304

- IP-: 40

- AC Rated: 6A 125V-250V

- Actuation Sequence(s): Break(1) Make(2)

- Contact Form(s): Form C

MN-5121

- IP-: 65

- AC Rated: 10A 250V

- Actuation Sequence(s): Break(1) Make (2)

- Contact Form(s): Form C